Marine Industry Specialists

The Heubach Corporation offers an array of foam products specifically designed for boat manufacturing and remodeling. We use state of the art foam fabrication equipment to meet your requirements. Our equipment makes it possible for us to engineer specialty foams, including anti-bacterial and anti-mould additives, natural fibers and plastics into a virtually endless amount of custom foam parts and assembled custom foam products suitable for any marine application. Using our advanced foam processing technology, we can fabricate different types...

read moreA Message From our CEO

The last few months have been incredibly challenging in more ways than we can possibly imagine. The coronavirus, Covid-19, started in China in December, and at first seemed a million miles away from affecting us as a country in the way that it now does. What started with a few cases of the disease has now led us to self-isolate in a way that the planet has never had to do ever in history. Fear, panic and feelings of isolation have been instilled in all of us. Our health system is being put under the most unique of strains, testing medical...

read moreFoam Fabrication

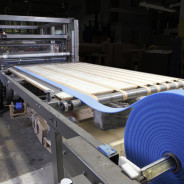

Foam Fabrication Heubach offers an array of custom foam products and foam fabrication services. We use state of the art foam fabrication equipment to meet your requirements. Our equipment makes it possible for us to engineer specialty foams, natural fibers and plastics into a virtually endless amount of custom foam parts, foam packaging products and assembled custom foam products. Using our advanced foam processing technology, we can fabricate different types and styles of foam including: reticulated polyurethane foam, open-cell foam...

read more3-D CNC Cutting

3-D CNC Foam Cutting We have the most accurate, state of the art horizontal foam 3-D CNC Cutting machines in the world. We can take your idea or specification and cut crosslink polyethylene, regular polyethylene or polyurethane foams into one piece 3 dimensional shapes. Our precision equipment will cut any shape, rotate the part 90 degrees and cut it again producing a part that meets your tightest tolerance requirements. Our 3-D CNC foam cutting machine follows CAD drawings to create complex foam fabricated products. Our seamless foam cutting...

read moreDie Cutting

Foam Die Cutting Heubach has commercial foam die cutting capabilities needed to produce thousands of parts a day. We provide a number of parts to the medical industry. Our steel rule foam die cutting conversion process enables us to attain the highest accuracies and the most efficient means of mass producing cut parts. The die-cut foam process uses steel rules dies that are custom shaped and mounted to our presses. Dies are built to tight tolerances and are used to cut your exact dimensional requirements. Our team designs your dies taking...

read moreAdhesive Laminations

Adhesive Foam Laminations Heubach has in-line capabilities to custom laminate roll stock, sheet stock, die cut parts, and many other substrates to meet your exact requirements. We can laminate foam materials including crosslink polyethylene foams, regular polyethylene foams, polyurethane foams, open-cell foam and closed-cell foam. Our advanced adhesive lamination capabilities enable us to do many types of adhesive laminations including heat melt or glue bonding laminating, solvent based adhesive, water based adhesives, and pressure sensitive...

read moreHeat Sealing/Bonding

Heat Sealing & Bonding of Foam Heubach has integrated heat bonding services, also known as thermal heat bonding, to extend our converting capabilities. Our processes can reduce the need for solvent based adhesives with aqueous adhesives, while maintaining structural part integrity at lower costs. In this process we utilize a hot air bonding machine or a heat gun to melt the surface of the substrates and then bond them together with pressure while they are still hot. We look forward to meeting your commercial and industrial bonding needs....

read moreMaterial Skiving

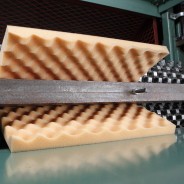

Foam Material Skiving Heubach Corporation continues to produce very tight tolerances on material thicknesses by using the worlds best skiving machine. Our machinery can split every material we stock to nearly exact dimensions. We can convert many materials from bun stock thickness all the way down to under 1/32″. Our skiver can slit rubber, and foams, including heavy density and high durometer materials. Foam skived products can be accurately skived into different shapes, sizes and thicknesses. Heubach’s skiving technology makes...

read moreHeat Thermoforming

Heat Thermoforming of Foam and Plastic Heubach provides custom vacuum and pressure thermoforming services for a variety of plastic materials. Our CAD/CAM technology ensures your products will be made to the exact specifications required. Thermoplastic sheets are made into 3-D shapes by using a clamp to hold the plastic, and then heating the plastic until it is pliable enough to be pressed into a mold. Once inside the mold, the thermoplastic sheet is shaped using vacuums and positive pressure. Heat thermoforming works well on plastics, but can...

read moreWater Jet Cutting

Foam Water Jet Cutting Our numerous water jet cutting equipment yields precision and consistency. Our custom water jet capabilities enable us to produce fast, accurate, tight tolerance parts. CAD equipment is used for maintaining accuracy and quality. We have the capability to water jet cut all types of foams and plastics, etc.. Our water jet cutters follow the CAD drawing in order to produce intricate shapes and cavities. Our water jet cutters all have multiple cutting heads with adjustable cutting pressure up to 60,000 psi. This results in...

read more