Heat Thermoforming of Foam and Plastic

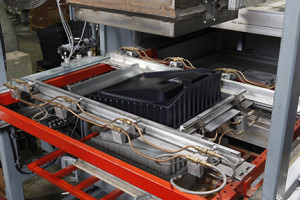

Heubach provides custom vacuum and pressure thermoforming services for a variety of plastic materials. Our CAD/CAM technology ensures your products will be made to the exact specifications required. Thermoplastic sheets are made into 3-D shapes by using a clamp to hold the plastic, and then heating the plastic until it is pliable enough to be pressed into a mold. Once inside the mold, the thermoplastic sheet is shaped using vacuums and positive pressure. Heat thermoforming works well on plastics, but can also be done on various types of foam.

We have the thermoforming capabilities to manufacture custom plastic and foam parts to your exact specifications. Our experience and CAM technology allow us to utilize pressure thermoforming, vacuum thermoforming and assembly to meet your requirements.

You can rely on our custom thermoforming services to help you introduce products quickly and price them competitively.